Prelab

PID Input Signal

The name of the game here is high quality orientation data. My IMU measures angular velocities in the directions of roll, pitch, and yaw, which means to get actual position, I need to integrate my values. This can cause some pretty bad drift over time.

One way I can minimize drift in my orientation data is by using arctangents of my IMU's accelerometer to find absolute position. The issue with this data alone is that it doesn't give me yaw, and it also gets unusably noisy when either the x or y components are near 0. So to compensate in these regions, I can rely more heavily on the gyroscope data.

In terms of sensor limitations, the ICM-20948 is a very capable sensor, but it does have a maximum degrees per second of rotation that it can measure. Similarly, it also has maximum acceleration and magnetic amplitude, but I think the rotational acceleration is going to be the first maximum that I hit, if I do. According to the ICM-20948's register mappings, the default gyroscope maximum degrees-per-second is +- 1000, which is around 3 revolutions per second. This should be sufficient for me, and I'll keep in mind not to go over this limit in my testing.

Sending and Receiving Data

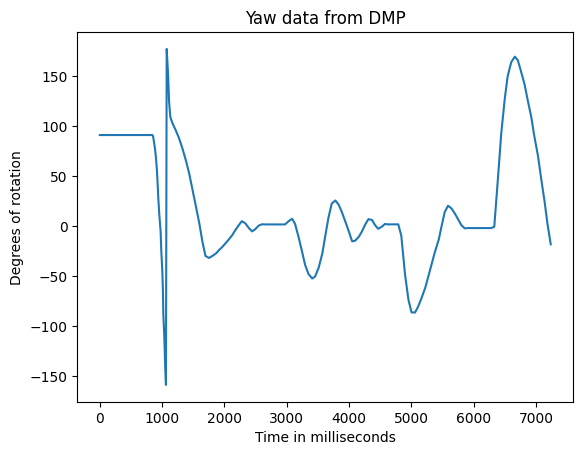

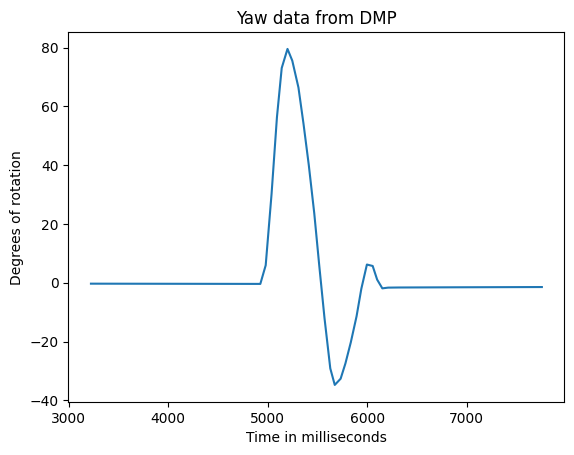

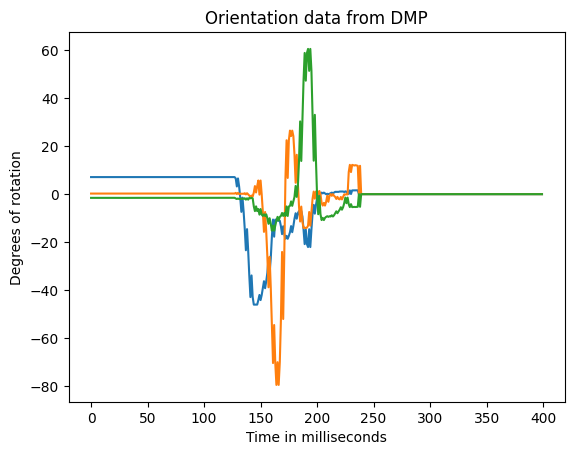

As I said before, with controls, high-quality data is key. The better your data is, the better the control. So, I need to be able to collect data from my Artemis, and send it to my PC for analysis. To do so, I used the example code from the ICM-20948 library to set up my DMP. After some basic functionality testing, I checked that the data I recieved to my PC matched what I expected based on the car's movement.

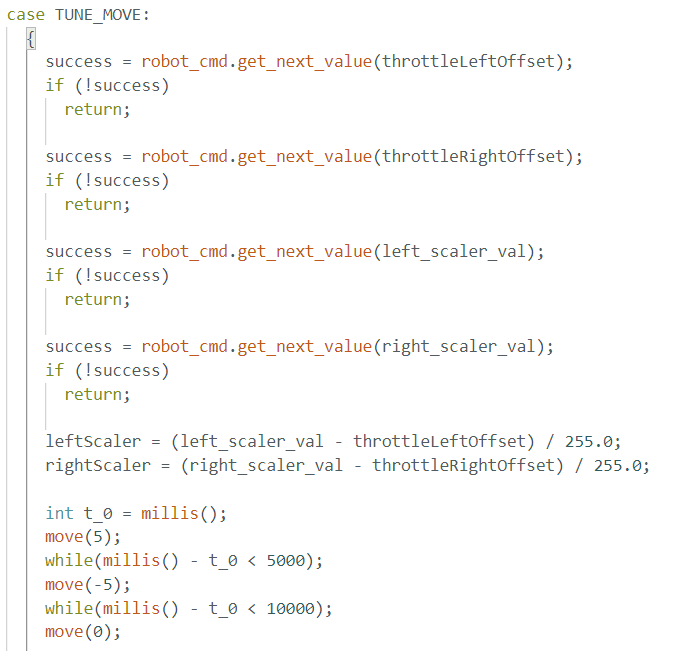

Once I was happy with the DMP data that I was collecting, I moved on to retuning my move() function. This function would take in a value between -255 and 255, and it would make the car rotate at a certain rate. Unfortunately, the static friction to overcome rotation is much higher than the static friction to overcome rolling forwards and backwards, so I had to retune my move() function. I did this using a temporary command over ble that would allow me to remotely change my tuning values:

This allowed me to rapidly find my offsets and scaling values for my left and right motors so that the robot would spin well in one spot.